Contact

Shipping Information

Fraunhofer PO Terms and Conditions

Fraunhofer Vendor Letter Shipping and Customs

Visiting and Delivery

Fraunhofer Innovation Platform for Composites Research

at Western

2520 Advanced Ave.

London, ON N6M 0E1

Tel: 519-661-2111 ext. 86975

vugresi@uwo.ca

Directions

Invoice Address

Western University,

Mechanical and Materials Engineering

Fraunhofer Innovation Platform for Composites Research

Claudette MacKay-Lassonde Pavillion

London, ON, Canada

N6A 5B9

Fraunhofer Equipment

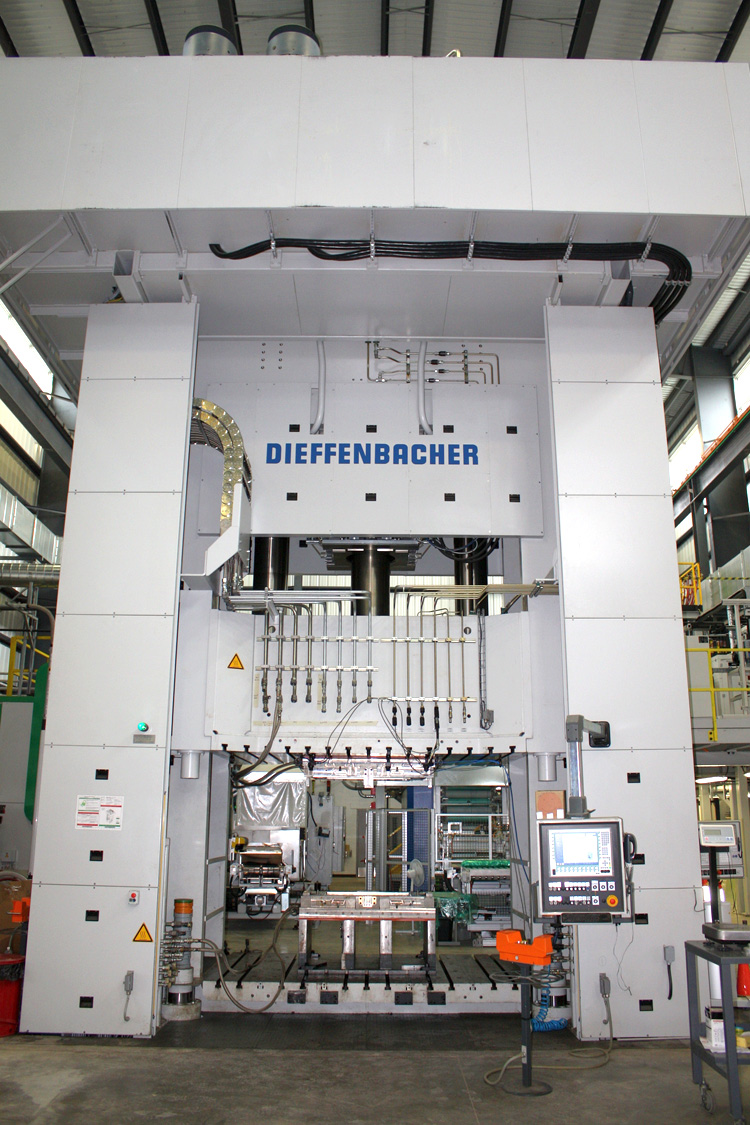

Compression Moulding

- Press with maximum clamping force of 2,500 tonnes

- Table size 3m X 2m

- Proactive parallelism control

- Moulding of demonstrator parts in industrial scale available

- Video

- Brochure

SMC

- Production trials

- Material and process development

- 400 mm to 800 mm sheet width

- Brochure

LFT-D

- 2 extruder configuration (Dieffenbacher process)

- Continuous fiber feeding

- Semi-structural part application

- Brochure

High Pressure RTM

- Automated Liquid Compression Moulding

- Compression and injection TRM

- Automated Liquid Compression Moulding

- Process development

- Alternative formulation development

- Brochure

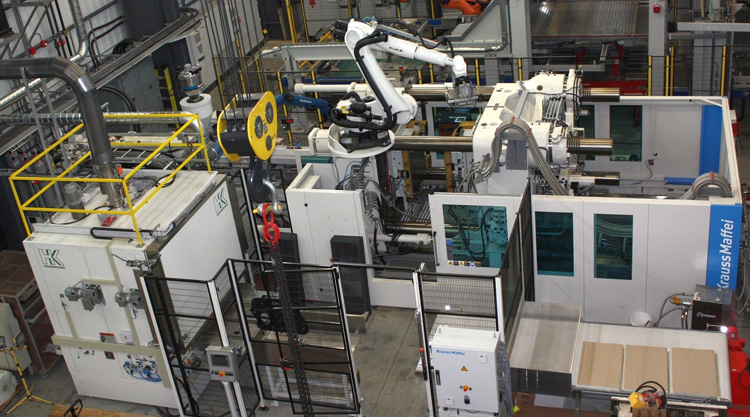

Injection Molding

- 1,600 ton and 550 ton equipment available

- Thermoset injection moulding

- Standard and MuCell injection unit with optimized long-fiber screw

(Ø = 120 mm) - Pressure accumulators for higher injection speed

- Fully automated manufacturing cell for continuous fiber reinforced parts

(circulating hot air furnace and 6 axis handling robot) - Brochure

Fiberforge RELAY® Station

- RELAY® technology

- Lay-up size up to 1m x 1m on two zones vacuum table

- Tape width: 50 - 150 mm

- Ultrasonic spot welding

- Brochure

Thermoset Injection Moulding

- 550 ton Arburg IM

- Thermoset & thermoplastic injection capability